Our Services

Alloy Development

Custom alloys and material solutions for advanced AM applications

Part/Component Design for AM

Optimized design for manufacturability and performance in AM

Engineering Consulting

Expert advice on AM processes, materials, and implementation

Prototyping & Validation

Rapid prototyping and thorough validation for industrial needs

Small Batch Production

Efficient, high-quality production of small series components

Documentation & Compliance

Comprehensive documentation and regulatory support

Projects & Portfolio

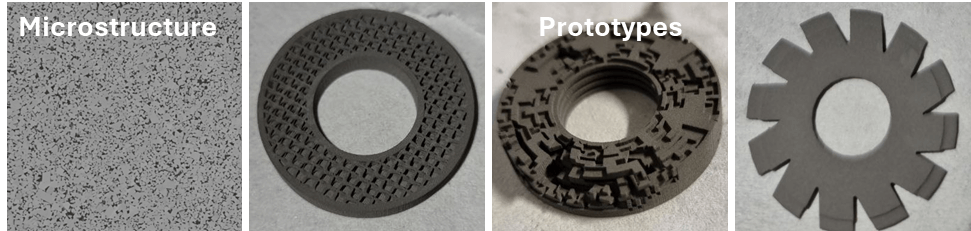

Additive Manufacturing of WC-12Co

- Near-net-shape cemented carbide parts with more than 99% density

- Hardness more than 1200 HV100 and TRS higher than 2200 MPa

- Unlocks flexible tooling and wear part designs, matching industrial standard performance

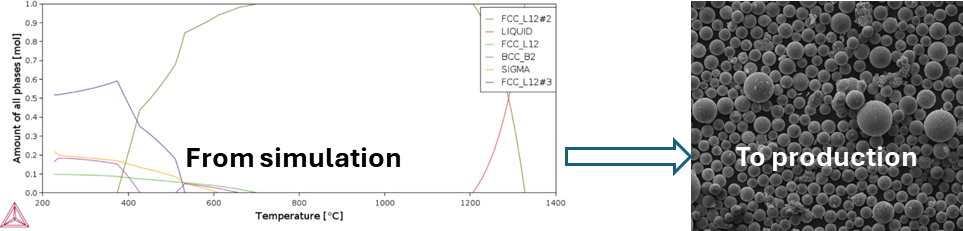

WC-HEA Cemented Carbide

- Development of CALPHAD designed sustainable cobalt-free high entropy alloy

- Enhanced hardness, higher than 1900 HV100.

- Next-gen cemented carbide with fine grained microstructure due to grain growth inhibition and lower cost by using recycled feedstock

Nb-based alloy for Extreme Temperature

- Spherical powder of complex Nb-Si-Al-Ti-Cr-Zr-Fe-Hf-Mo alloy developed for additive manufacturing

- Engineered for aerospace and energy application. 760 MPa @ 1200°С; 380 MPa @ 1300°С

- Full-cycle workflow from alloy design to validation with L-PBF and SPS

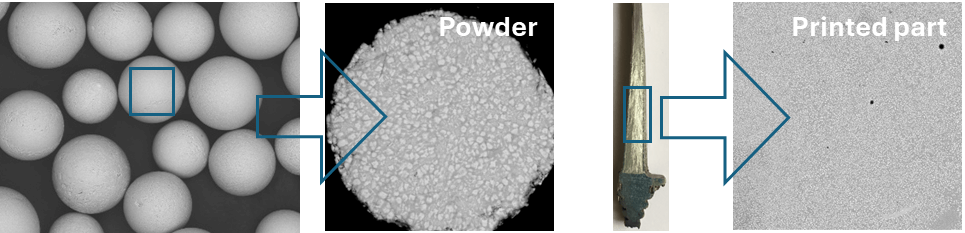

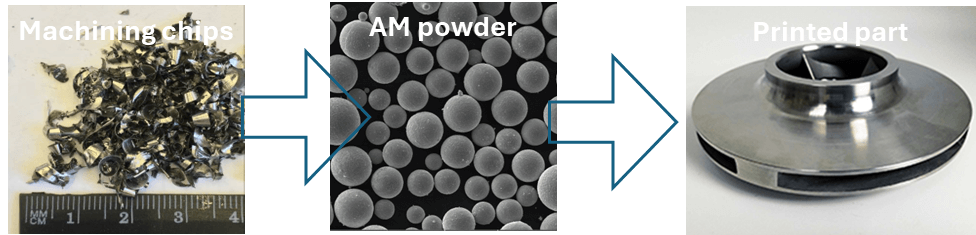

Recycled Powder for Sustainable Additive Manufacturing

- Recycling machining waste into AM-ready powders, 95%+ sphericity

- Up to 80% reduction in feedstock cost for high-alloy steel

- Verified by L-PBF and L-DED: High-strength, improved ductility after heat treatment

About Us

Ivan GoncharovAM Materials expert

Ivan GoncharovAM Materials expertMaterials scientist with over 10 years of experience in powder metallurgy, alloy development and additive manufacturing.

Dual PhD in the design of high-performance materials for extreme environments, such as cemented carbides, high-temperature alloys, functional materials.

CALPHAD simulation, Binder Jetting, Laser Bed Powder Bed Fusion, Plasma Spheroidizaion, Ultrasonic Atomization, Spark Plasma Sintering.

20+ Scientific publications.

Led and worked on several multidisciplinary international projects from material design to process validation.

LinkedIn

LinkedIn Benjamin Meier-LeebAM Process expert

Benjamin Meier-LeebAM Process expertMechanical engineer with 10+ years of experience in additive manufacturing process development, material and powder behavior characterization across research institutes and industry.

PhD in Laser Powder Based Fusion with wide exposure on titanium alloys, special steels, aluminium alloys and functional materials.

CAD, Laser and Electron Beam Powder Bed Fusion, Laser Directed Energy Deposition.

15+ scientific publications.

Led and contributed to numerous European R&D projects in Austria and Italy.

LinkedIn

LinkedIn Michele ZanettiAM Machines expert

Michele ZanettiAM Machines expertApplication and Service Engineer with over 5 years of experience in industrial additive manufacturing.

Laser Powder Bed Fusion, Stereolithography, Selective Laser Sintering, Fused Filament Fabrication.

Vast hands-on experience with hardware from installation to maintenance and training enables to form expert unbiased opinions and technical in-field depth helps to guide customers with technology transfer.

LinkedIn

LinkedIn